- Innovative breakthrough of large metal polishing machine: magnetic polishing

- Magnetic polisher and plane polisher: Gemini of precision manufacturing

- Why magnetic polishers process metal surfaces so quickly

- Guan Gu magnetic polishing machine removes high-temperature oxidation color of metal

- Magnetic polishing machine actual measurement: aluminum radiator polishing and deburring effect is significant

- Magnetic polishing machine: a tool beyond metal surface treatment

E-mail:[email protected]

Phone:18626103335

TEL:400-800-3945

Address:No. 333, Zixu Road, Xukou Town, Wuzhong District, Suzhou

Magnetic needle polishing machine for oil and air pump joint accessories cleaning and polishing manufacturers case

Oil air pump joint fittings are often used in the production and manufacture of air pump joint, which belongs to a kind of Aluminum die casting parts. There are many manufacturers of aluminum die casting parts. Air pump joint manufacturers often consider that the surface of the joint fittings is flat and metallic when choosing the oil pump joint fittings. Therefore, after processing of the oil pump joint fittings, the surface often needs to be cleaned and polished.

cleaning and Polishing of oil pump joint fittings can be better used in the production and manufacture of air pump joint. So how to clean and polish the oil pump joint accessories? This is a common problem in many manufacturers of oil and air pump fittings. Today, Guan Gu Technology introduces to you the case of Magnetic needle polishing machine for cleaning and polishing of oil and air pump joint accessories manufacturers.

The picture below is a real shot of the joint fittings of the oil and air pump, which is a multi-joint irregular shaped aluminum part with threaded holes. It can be seen that the surface problems of the joint fittings of the oil and air pump are obvious. The surface is black and uneven, which needs to be cleaned and polished.

In order to remove the black potholes and uneven surface of the oil and air pump joint fittings, the next use of crown ancient magnetic needle polishing machine to clean and polish the oil and air pump joint fittings.

Select the appropriate magnetic needle according to the size of the oil and air pump fittings, and use the magnetic needle to clean and polish the oil and air pump fittings.

Pour water into the groove of the magnetic needle polishing machine, which can flood the oil and air pump joint fittings:

Pour the polishing liquid to increase the metal luster on the surface of the oil air pump joint fittings:

Put into the sample of oil air pump joint fittings:

Cleaning and polishing of air pump fittings:

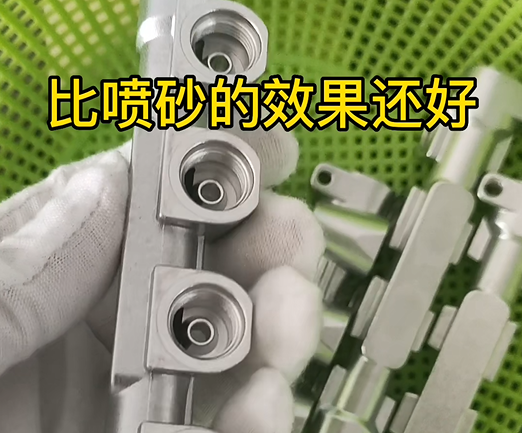

According to the size and material of the oil and air pump joint fittings, wait for the corresponding time. After the cleaning and polishing of the oil and air pump joint fittings, remove the surface moisture of the oil and air pump joint fittings. The following is the cleaning and polishing effect of the oil and air pump joint fittings, and the surface of the oil and air pump joint fittings is smooth and metallic.

Black pits and uneven surfaces on the oil and air pump joint fittings have been removed, and the surface of the joint fittings is flat and metallic, restoring the metal color of the oil and air pump joint fittings:

The multi-joint irregular shape aluminum parts with threaded holes are handled well. The above is the case of cleaning and polishing manufacturers of oil and air pump joint accessories. The manufacturers who need to remove the black potholes and uneven surfaces of the workpiece need polishing are welcome to consult.

- Previous:Magnetic polishing machine to stainless steel martial arts tool handle polishing cleaning manufacturer's case

- Next:Operating rules for magnetic metal polishing machine to deburr and deoxidize round gaskets of aluminum parts

-

2022-10-18Deburring of stainless steel stampings